Product Introduction

Beyond the Limits of Cutting, Setting the Standard for the Future

Redefining the laser industry

Advantages of JL Laser Steel Cutting Machine

Wider, Longer, Redefining the Scale of Cutting

Wider, Longer, Redefining

the Scale of Cutting

- A perfect solution for large structures with a width of 5m and a length of up to 50m

- Precision without length limitations, powered by JL Laser technology

- The optimal equipment for processing large ship structures and marine construction materials

Vibration-free cutting, error-free results.

- Precisely cuts 25mm thick plates in a single pass, vertically.

- Delivers excellent finish quality without the need for post-processing.

- The difference made by high-power fiber technology.

Maximizing convenience in operations.

- Clean vertical cutting of 30mm thickness.

- The essence of high-power fiber laser technology.

Complex cuts made in one go, bevel cutting solution.

Complex cuts made in one go,

bevel cutting solution.

- Bevel cuts up to 45 degrees, with full flexibility.

- Provides optimal processing conditions before welding.

- High-precision bevel cutting, completed without additional processing.

- Cutting technology optimized for the creation of 3D structures.

Zero collisions, Zero accidents.

- Ensuring worker safety

- Equipped with automatic stop function

- Optical barrier system linked with the laser head

With JL Industrial Machinery's technology, more precisely.

With JL Industrial Machinery's technology,

more precisely.

- Enhanced beam structure for stable, vibration-free cutting

- Evolution of structural design to improve cutting precision

- Stability maintained even during high-speed cutting with reinforced beam structure

- Durability design that ensures no vibration during long cutting times

Clean cuts, the beginning of a pleasant working environment

- Immediately dust generated during high-power cutting

- Smart dust collection design considering the worker’s health

- Powerful dust collection system that captures even invisible dust

No post-processing required for the cutting surface

- The cutting surface is smooth with minimal oxidation.

- Can be applied directly to subsequent processes without post-processing.

- Maintains precision and consistency without quality degradation, even in high-speed cutting.

Real-time precise control of gas pressure and flow rate.

Real-time precise control of

gas pressure and flow rate.

- Perfect control of any gas (nitrogen, oxygen, steam)

- Continuous cutting without process interruption

- Automatic gas setting switch

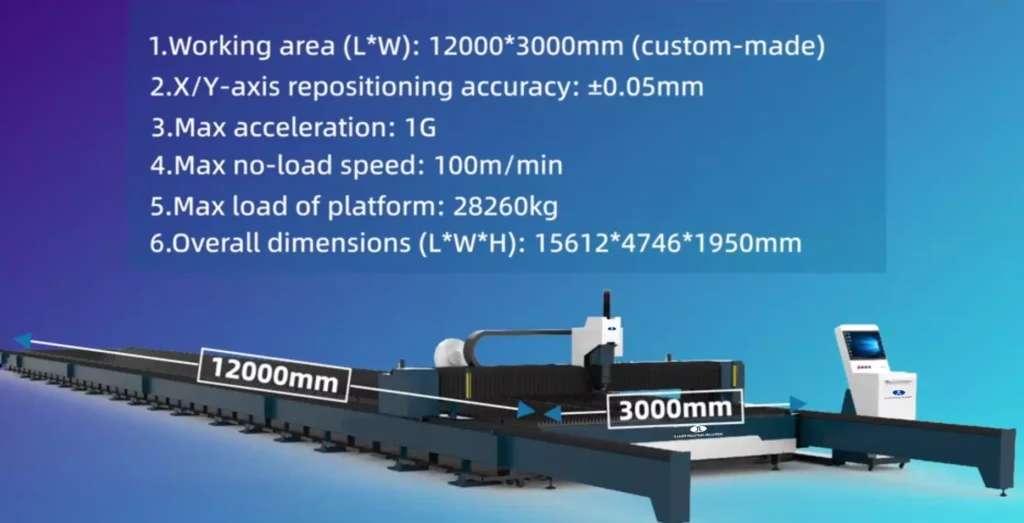

Fiber Laser Specifications

- Working Area (L×W): Length 10m ~ 50m / Width up to 5m (Customizable)

- X/Y Axis Repositioning Accuracy: ±0.05mm

- Maximum Acceleration: 1G (High-speed Responsiveness)

- Maximum Travel Speed without Load: 100m per minute

- Maximum Platform Load: 28,260kg (Can be adjusted based on specifications)

- Overall Equipment Dimensions (L×W×H): 15,612 × 4,746 × 1,950mm