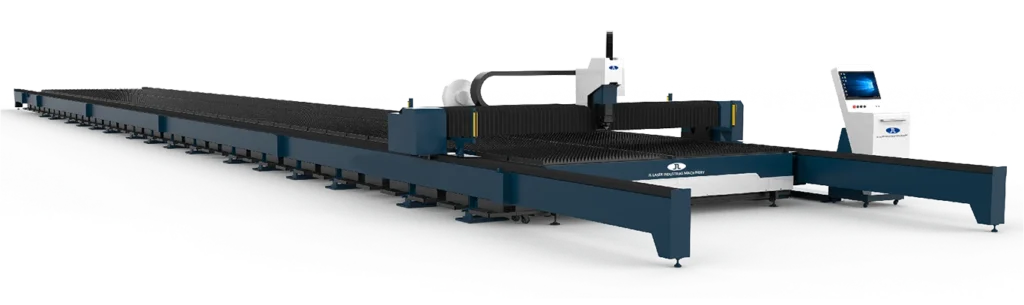

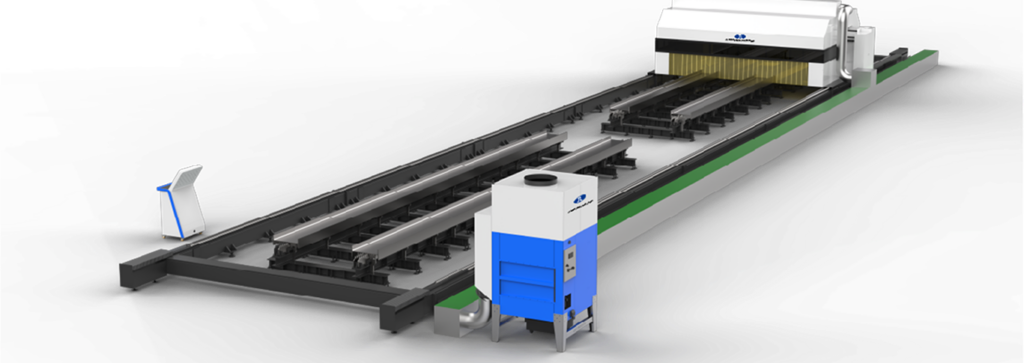

Large H-Beam Steel Laser

Cutting Production Line

Processes large H-beams quickly and precisely

with a high-rigidity dual-drive structure and

a semi-enclosed double-station design.

NC Auto-Conversion Solution,

JLCut

Connect design data to laser cutting

with just one click.

JL Tekla Component

Transfer Tekla-based 3D design data directly to JL's cutting machine.

Applications

Laser cutting machines are widely used in industries such as aerospace, steel structures, and construction.

They enable precise and fast cutting of components, making them preferred in heavy industries.

Thanks to their fast and precise processing capabilities, they have become a key choice for industrial applications.

Laser cutting machines are widely used in industries such as aerospace, steel structures, and construction.

They enable precise and fast cutting of components, making them preferred in heavy industries.

Thanks to their fast and precise processing capabilities, they have become a key choice for industrial applications.

Shipbuilding & Offshore

The ever-evolving shipbuilding and offshore industry is seeing a surge in demand for more efficient manufacturing methods and advanced equipment. Thanks to continuous technological advancements, this growth has been driven by groundbreaking developments in shipbuilding materials and construction technologies. The industry, which has largely relied on steel plates, has extensively used plasma cutting.

However, amidst these advancements, many laser cutting technologies have brought about a pivotal transformation in manufacturing processes, boasting remarkable efficiency, precision, and environmental sustainability.Laser cutting equipment has become the shipyard's best partner, enhancing supply chain efficiency.

Construction / Steel

Fabricating steel structures is one of the most common applications of laser cutting equipment. In most cases, steel plays a key role in connecting the use of laser cutting machines at construction sites.In construction projects, using laser cutting machines offers significant advantages, as they can efficiently and precisely cut thick steel plates.

Other Industries

In today's rapidly advancing manufacturing industry, laser cutting technology has become an essential core technology in various fields such as metal processing, automotive manufacturing, aerospace, and consumer electronics, thanks to its high precision, efficiency, and flexibility.Laser cutting machines, leading this technology, are driving innovation and progress in the industrial manufacturing sector based on their unique advantages.

Laser cutting machines, a crucial tool in modern industry, have demonstrated significant potential for application and development across various fields.Through constant innovation and improvement of the technology, laser cutting machines are expected to play an increasingly important role in more fields, driving sustainable development and progress in industrial manufacturing.

Technological Innovation

Laser Marking

It offers excellent durability, strong resistance to chemical reactions, and is environmentally friendly. It enables marking that is resistant to corrosion and wear.

Powder Marking

It provides high-temperature resistant and highly durable marking, making it widely used for industrial components. The markings are deeply engraved and highly durable, allowing reliable performance even in extreme environments

UV Inkjet Marking

It offers fast printing speed and allows for precise design marking. UV ink cures quickly, enhancing productivity. In addition, the marked areas are highly durable and adhere well to a wide range of materials

3D Cutting

3D cutting is a technology that precisely cuts three-dimensional shapes or complex forms using lasers or other cutting techniques. Unlike general 2D cutting, which is performed on a flat surface, 3D cutting is a method that allows for processing three-dimensional objects or parts into freeform shapes.